☞ Molemo

1. Tshireletso

Pipe ea tšepe e tiisa matla a boima, bokaholimo ba polasetiki bo boreleli ho fokotsa tšenyo ea likarolo le kotsi ho basebetsi mosebetsing.

2. Boemo ba maemo

Ikamahanye le litlhoko tsa ISO9000 le QS9000.Bophahamo bo tloaelehileng le bolelele le lisebelisoa tse tsamaellanang le tsona li etsa hore e be matla a fapaneng.

3. Bonolo

Ntle le tlhaloso ea mojaro, phala e omeletseng le lihlahisoa tsa tsamaiso e kopanetsoeng ha ho hlokahale hore li nahane ka lintlha tse ngata tse nepahetseng le melao ea meralo.Basebetsi ba mehala ea tlhahiso ba ka li rala le ho li etsa ka bobona ho latela maemo a bona a seteishene.Ho hlokahala wrench e le 'ngoe feela ea M6 ea hexagonal ho phethela tšebetso ea ho kenya.

4. Ho tenyetseha

E ka etsoa, ea bokelloa le ho lokisoa ho latela litlhoko tsa eona tse khethehileng ntle le ho lekanyetsoa ke sebopeho sa likarolo, sebaka sa sebaka sa mosebetsi le boholo ba sebaka.

5. Scalability

E tenyetseha, e bonolo ho e fetola, 'me e ka holisa sebopeho le ho sebetsa kamoo ho hlokahalang ka nako efe kapa efe.

6. Sebelisa hape

Lipeipi tse omeletseng le lihlahisoa tsa sistimi e kopaneng li maemong 'me li ka sebelisoa hape.Ha potoloho ea bophelo ba sehlahisoa kapa ts'ebetso e fela, sebopeho sa liphaephe le manonyeletso a se nang mafura a ka fetoloa 'me likarolo tsa pele li ka kopanngoa litsing tse ling ho finyella litlhoko tse ncha, kahoo boloka litšenyehelo tsa tlhahiso le ho tšehetsa tšireletso ea tikoloho.

7. Ntlafatsa katleho ea tlhahiso le ho ntlafatsa boleng ba basebetsi

Pipe e fokolang le tsamaiso e kopanetsoeng li ka tsosa tlhokomeliso ea boqapi ba basebetsi.Ntlafatso e tsoelang pele ea lihlahisoa le lits'ebetso li ka ntlafatsa ts'ebetso ea tlhahiso le ho ntlafatsa boleng ba basebetsi, ho hlokomela taolo ea tlhahiso e fokolang.

☞ Mokhoa oa ho etsa Lean Pipe le Manonyeletso Sistimi?

1. Boitokisetso:

1.1 Kgetha sebopeho le setaele se nepahetseng

Ka lebaka la mesebetsi e fapaneng, ho na le liphapang tse 'maloa ka sebopeho le setaele sa lits'ebetso tse ts'oanang tsa sistimi ea liphaephe.Mokhoa oa ho khetha sebopeho le mokhoa o nepahetseng ka ho fetisisa o na le kamano e ntle le ts'ebetso ea ts'ebetso.Haeba u sa tsebe ho khetha mefuta, ka kopo ikopanye le rona.

1.2 Netefatsa ho Rala le Moralo Setšoantšo se ka bolela esale pele mathata a ka bang teng ts'ebetsong ea tlhahiso le ho a lokisa ka nako, ho thibela ho tsosolosoa ha tlhahiso le ho senya nako le thepa.Ha ho na le meralo e mengata, moralo oa mohopolo oa pele o ka etsoa bakeng sa morero o mong le o mong mme litšoantšo tse tsamaellanang li ka huloa kahohle kamoo ho ka khonehang.Bala lisebelisoa tse hlokahalang, hlahloba bothata ba tlhahiso, 'me u buisane le basebetsi-'moho le lefapha ka bothata bo pharaletseng ba tlhahiso le litšenyehelo ho fumana moralo.

1.3 Theha Lethathamo la Litlhoko tsa Lintho

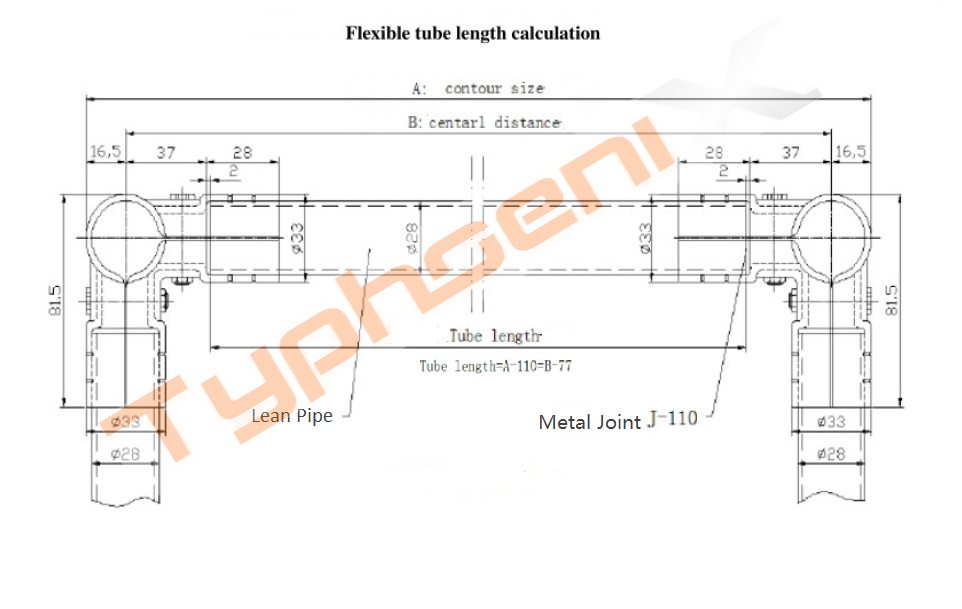

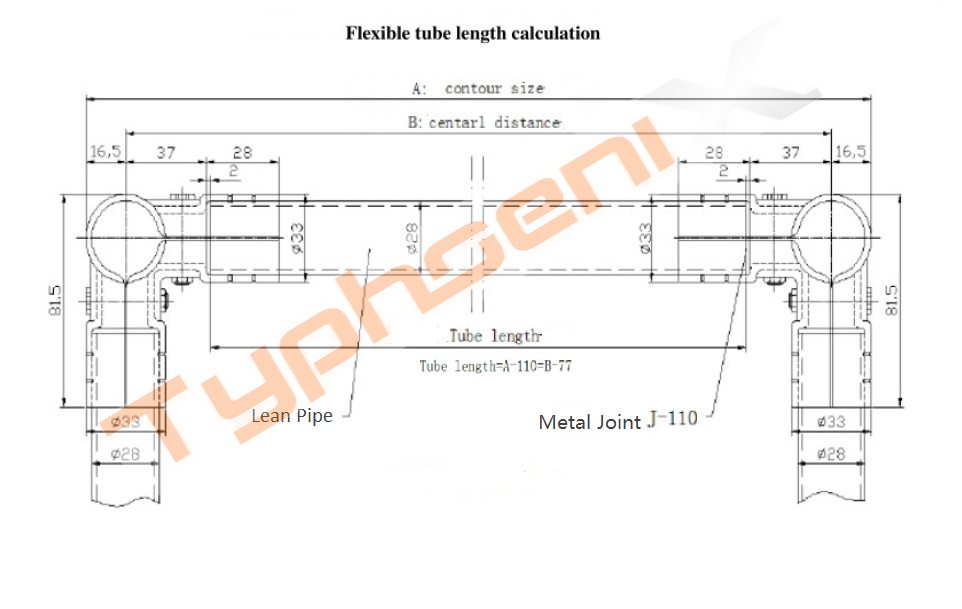

| Linonyello tsa tšepe le lisebelisoa tse ling li ka rekoa ho latela mofuta le boholo ba litšoantšo, ha bolelele bo tloaelehileng ba phala e omeletseng e le limithara tse 4, e lokela ho khaoloa pele e sebelisoa.Ho eketsa tšebeliso ea phala e se nang mafura ho qoba litšila, lethathamo la liphaephe tse fokolang le lokela ho etsoa le ho le khaola ka nepo.Setšoantšo se ka tlase se bontša setšoantšo sa lipalo sa bolelele ba phala e omeletseng.Bolelele ba ho itšeha ha phala e omeletseng karolong e 'ngoe le e' ngoe e ka baloa ka litšupiso le ho eketsoa lethathamong la tlhokahalo ea lintho tse bonahalang. |

|

1.4 Lokisetsa lisebelisoa

Lisebelisoa tse hlokahalang bakeng sa ho etsa liphaephe tse fokolang le litsamaiso tse kopanetsoeng li kenyelletsa:

•Mochini o sehang: o sebedisoang ho seha liphaephe tse omeletseng.Haeba u sa batle ho hlomella mochine oa ho itšeha, re ka fana ka tšebeletso ea ho itšeha phala, ho fana ka bolelele bo lekanang le bongata ba phala e otlolohileng ho latela litlhoko tsa hau. •Allen wrench: Se sebedisoang ho hokela phala e tshesane le manonyeletso a tshepe •Tape measure/ Ketso ya ho lekanya: lekanya bolelele ba phala e tshesane • Lesupa: ho tshwaya •Curve saw le drill ea letsoho ea motlakase: e sebelisetsoang ho seha le ho phunya phanele e sebetsang hantle (haeba ho hlokahala)

1.5 Lokisetsa thepa

Lokisetsa lisebelisoa tsohle tse thathamisitsoeng ho 1.3 The Material Demand List, ebe u qala ho etsa.

2. Tlhahiso

2.1 Ho Seha Peipi e Lean

Sebelisa tepi ho lekanya bolelele ba phala e omeletseng le ho tšoaea boemo ba ho seha ka lesupa.Ka kopo etsa bonnete ba hore bolelele bo lumellana le lethathamong la lintho tse bonahalang, ho seng joalo, phala e fokolang le tsamaiso ea manonyeletso e tla be e sa lekane, 'me mohaho o tla ba o sa tsitsang.

Ka nako e ts'oanang, ka kopo sebelisa faele ho tlosa li-burrs tse hlahisitsoeng ha ho khaola phala, hobane li-burrs li ka 'na tsa hlaba batho' me tsa etsa hore ho be thata ho kenya sekoahelo se ka holimo.

2.2 Ho kenya sebopeho sa foreimi ea lipeipi tse omeletseng

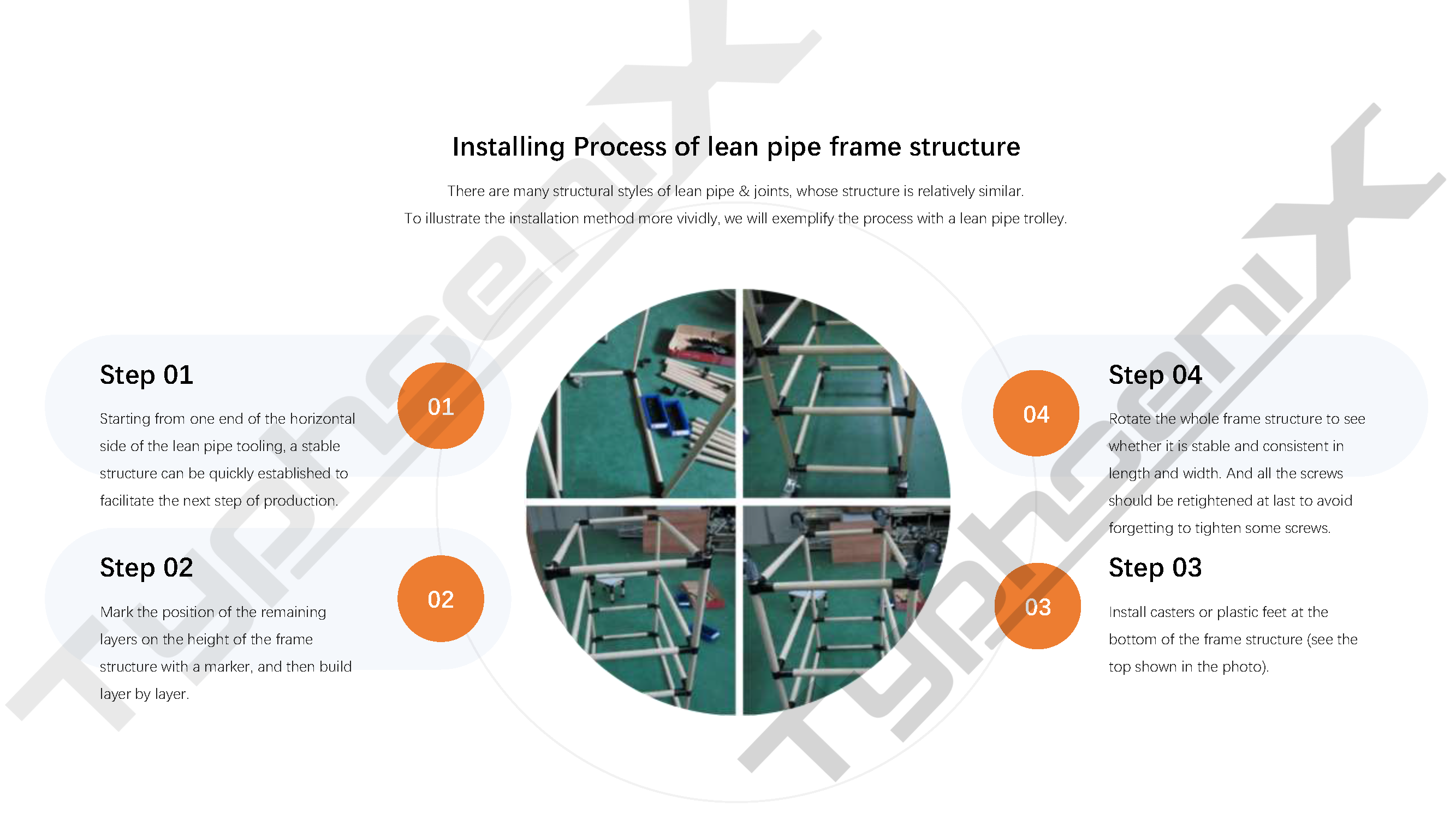

Ho na le mekhoa e mengata ea meralo ea liphaephe le manonyeletso, tseo sebopeho sa tsona se batlang se tšoana.Ho bontša mokhoa oa ho kenya ka mokhoa o hlakileng haholoanyane, re tla etsa mohlala oa ts'ebetso ka trolley ea pipe e omeletseng.

① Ho qala ho tloha pheletsong e 'ngoe ea lehlakoreng le otlolohileng la lisebelisoa tsa phala ea lean, mohaho o tsitsitseng o ka thehoa ka potlako ho tsamaisa mohato o latelang oa tlhahiso.

Hlokomela:Pipe e omeletseng e sebelisoang mokatong oa pele e tlameha ho lumellana ka bolelele, bophara le bophahamo, ho seng joalo E tla kenngoa ka sebopeho se sa tloaelehang.

②Tšoaea boemo ba lihlopha tse setseng bophahamong ba sebopeho sa foreimi ka lesupa, ebe u haha lera ka lera.Likarolo tsohle tsa tšepe le liphaephe tse omeletseng li tla kenngoa sebakeng ho latela litlhoko tsa moralo ho etsa bonnete ba hore sekoti se seng le se seng sa tšepe se tiisang sebaka.Ha e lumelloe ho otla liphaephe le manonyeletso ka hamore e thata.Ha u kenya mohala, etsa bonnete ba hore o pota-potile fatše, ho qoba tšenyo e bakiloeng ke matla a sa lekaneng holim'a foreimi eohle.

③ Kenya li-caster kapa maoto a polasetiki ka tlase ho sebopeho sa foreimi (sheba holimo ho bontšitsoe setšoantšong).

Hlokomela:Ela hloko ho tiisa li-screws ho li-casters.Ka ho tiisa butle-butle ha li-screws, selikalikoe sa rabara ka har'a li-casters se tla atoloha butle-butle, 'me qetellong, se tla kenngoa ka thata ka har'a tube e omeletseng.Haeba li-screws li sa tiisetsoe, trolley ea peipi e tšesaane e tla oela ha e sututsa, e leng se tla baka tšenyo ea thepa kapa likarolo tse ling.

④Fetola sebopeho sohle sa foreimi ho bona hore na se tsitsitse le ho ts'oana ka bolelele le bophara.'Me li-screw tsohle li lokela ho tiisoa hape ho qoba ho lebala ho tiisa li-screw.

⑤ Kenya poleiti le lisebelisoa tse ling ho foreime ho fihlela litlhoko tsa 'nete tsa mosebelisi.

3. Ho hloekisa

Hloekisa sebaka sa mosebetsi ho tsamaisa mosebetsi o mong.Mekhoa e metle ea ho sebetsa ke tiiso ea katleho e phahameng ea mosebetsi.Re tlameha ho hlaolela mekhoa e metle mosebetsing oa rona oa letsatsi le letsatsi.6S e bohlokoa haholo taolong ea setšeng le mosebetsing oa letsatsi le letsatsi.

Basebeletsi ba tlhahiso ea liphaephe le litsamaiso tsa manonyeletso hangata ba hloka batho ba 2-3, 'me ha ho na tlhoko e tiileng mabapi le bokhoni ba basebetsi.Leha ho le joalo, liphaephe tse fokolang le litsamaiso tse kopanetsoeng li sebetsa haholo 'me e le lisebelisoa tsa tlhahiso le ts'ebetso ea k'hamphani, li lokela ho nkoa ka botebo.

Ka nako e ts'oanang, liphaephe tse omeletseng le litsamaiso tse kopanetsoeng ka kakaretso li kholo ebile li fapane ka sebopeho, 'me litsebo tse ngata ts'ebetsong ea ho kenya li ke ke tsa hlalosoa ka mantsoe a qaqileng.Sehlooho sena se fana ka kenyelletso e khutšoanyane feela, e sa bontšeng ka ho feletseng litsebo le mohloli oa tlhahiso ea liphaephe le litsamaiso tse kopanetsoeng.Ka nako e ts'oanang, ho tla ba le liphoso tse itseng nakong ea ho hlophisa.Haeba u fumana mathata a itseng kapa u na le maikutlo kapa litlhahiso, ka kopo ikopanye le rona.