☞ Inzuzo

1. Ezokuphepha

Ipayipi lensimbi liqinisekisa umthamo wokukala, indawo yepulasitiki ibushelelezi ukuze kuncishiswe umonakalo ongaphezulu wezingxenye nokulimala kwabasebenzi emsebenzini.

2. Ukumisa

Ukuhambisana nezidingo ze-ISO9000 kanye ne-QS9000.Ububanzi obujwayelekile nobude kanye nezinsiza ezijwayelekile ezifanayo kubenza babe nezinto ezihlukahlukene eziqinile.

3. Ubulula

Ngokungeziwe encazelweni yomthwalo, ipayipi elithambile nemikhiqizo yesistimu ehlanganyelwe ayidingi ukucabangela idatha enembe kakhulu nemithetho yesakhiwo.Abasebenzi bomkhakha wokukhiqiza bangakwazi ukuziklama futhi bazikhiqize ngokwabo ngokwemibandela yabo yesiteshi.Kudingeka isikrufu esisodwa esingu-M6 esiyi-hexagonal ukuze kuqedelwe inqubo yokufaka.

4. Ukuvumelana nezimo

Ingaklanywa, ihlanganiswe futhi ilungiswe ngokuya ngezidingo zayo ezikhethekile ngaphandle kokunqunyelwa ukuma kwezingxenye, isikhala sendawo yokusebenza kanye nosayizi wesayithi.

5. Ukuqina

Iyavumelana nezimo, kulula ukuyiguqula, futhi inganweba ukwakheka nokusebenza njengoba kudingeka noma kunini.

6. Sebenzisa kabusha

Ipayipi elithambile kanye nemikhiqizo yesistimu ehlanganyelwe isezingeni futhi ingasetshenziswa kabusha.Lapho umjikelezo wempilo yomkhiqizo noma inqubo iphela, ukwakheka kwamapayipi athambile namajoyinti kungashintshwa futhi izingxenye zangempela zingahlanganiswa kabusha kwezinye izikhungo ukuze kuhlangatshezwane nezidingo ezintsha, ngakho-ke yonga izindleko zokukhiqiza futhi usekele ukuvikelwa kwemvelo.

7. Ukuthuthukisa ukusebenza kahle kokukhiqiza nokuthuthukisa izinga labasebenzi

Ipayipi elithambile kanye nesistimu ehlanganyelwe kungavusa ukuqwashisa okusha kwabasebenzi.Ukuthuthukiswa okuqhubekayo kwemikhiqizo nezinqubo kungathuthukisa ukusebenza kahle kokukhiqiza futhi kuthuthukise ikhwalithi yabasebenzi, ukuze kubonwe kangcono ukuphathwa kokukhiqiza okunciphile.

☞ Indlela Yokwenza Ipayipi Lean Nesistimu Yamalunga?

1. Ukulungiselela:

1.1 Khetha isakhiwo nesitayela esifanele

Ngenxa yemisebenzi ehlukene, kunomehluko eminingana esakhiweni nasesitayeleni sezinhlelo zokusebenza zesistimu yamapayipi anomzimba ofanayo.Indlela yokukhetha isakhiwo esifanele kakhulu nesitayela sinobudlelwane obuhle nokufezekiswa komsebenzi.Uma ungazi ukuthi ungakhetha kanjani amamodeli, sicela usithinte.

1.2 Qinisekisa Umdwebo kanye Nesu Umdwebo ungabikezela izinkinga ezingaba khona enqubweni yokukhiqiza futhi uzilungise ngesikhathi, ukuvimbela ukusetshenzwa kabusha ohlelweni lokukhiqiza nokumosha isikhathi nezinto zokwakha.Uma kunamasu amaningana, umklamo womqondo wokuqala ungenziwa ohlelweni ngalunye futhi imidwebo ehambisanayo ingadwetshwa ngokusemandleni.Bala izinto ezidingekayo, hlaziya ubunzima bokukhiqiza, bese uxoxisana nozakwethu bomnyango ngobunzima bokukhiqiza obuphelele kanye nezindleko zokunquma uhlelo.

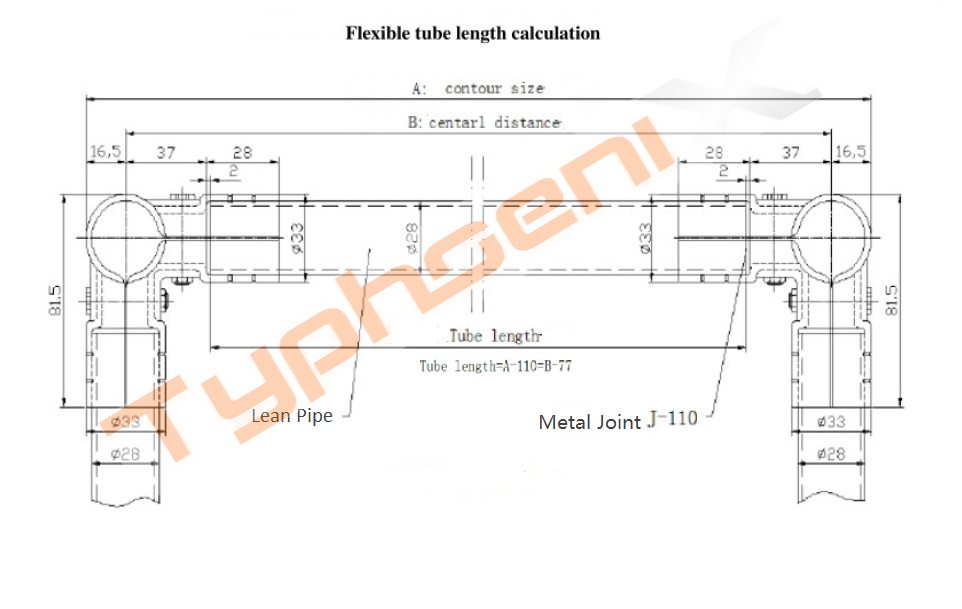

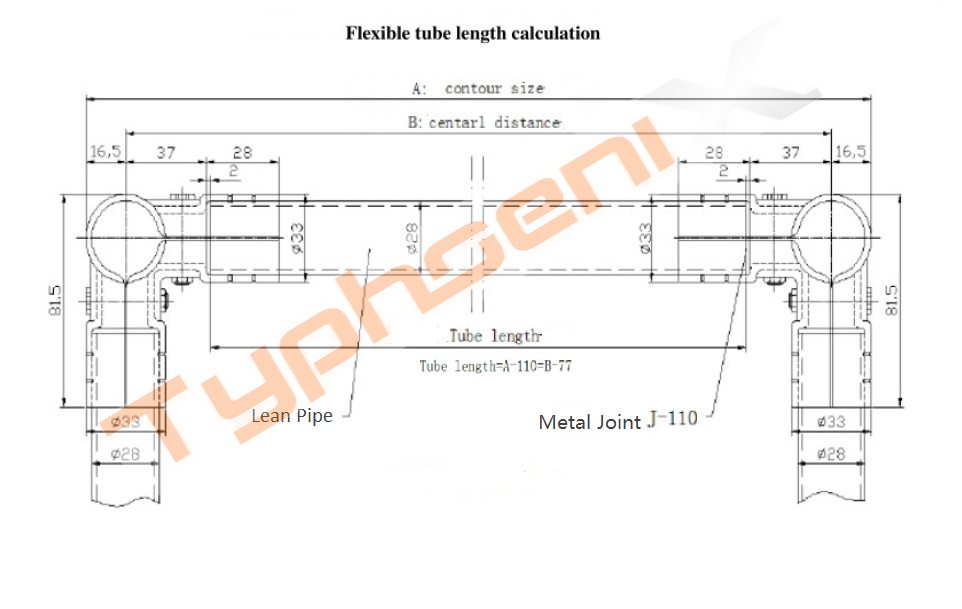

1.3 Dala Uhlu Lwezidingo Ezibalulekile

| Izihlanganisi zensimbi nezinye izesekeli zingathengwa ngokusho kohlobo nobuningi bemidwebo, kuyilapho ubude obujwayelekile bepayipi elithambile lingamamitha angu-4, lidinga ukunqunywa ngaphambi kokusetshenziswa.Ukuze kwandiswe ukusetshenziswa kwepayipi elithambile ukuze kugwenywe ukungcola, uhlu lwamapayipi anciphile ludinga ukwenziwa futhi lusikwe ngokufanele.Umfanekiso ongezansi ubonisa umdwebo wokubala wobude bepayipi elithambile.Ubude bokusika bepayipi elithambile engxenyeni ngayinye bungabalwa ngereferensi futhi yengezwe ohlwini lwezidingo zezinto ezibonakalayo. |

|

1.4 Lungiselela amathuluzi

Amathuluzi adingekayo ekukhiqizeni amapayipi amancane kanye nezinhlelo ezihlangene ahlanganisa:

•Umshini wokusika: osetshenziselwa ukusika amapayipi amancane.Uma ungafuni ukuhlomisa umshini wokusika, singahlinzeka ngensizakalo yokusika ipayipi elithambile, ukuhlinzeka ngobude obuhambisanayo kanye nenani lepayipi elithambile ngokwezidingo zakho. •I-Allen wrench: isetshenziselwa ukuxhuma ipayipi elithambile namajoyinti ensimbi •I-tape measure: kala ubude bepayipi elithambile • Umaka: ukumaka •I-Curve saw kanye ne-electric hand drill: isetshenziselwa ukusika nokubhola iphaneli ye-worktable (uma kudingeka)

1.5 Lungisa izinto zokwakha

Lungiselela zonke izinto ezisohlwini 1.3 ku-Material Demand List, bese uqala ukwenza.

2. Ukukhiqiza

2.1 Ukusika ipayipi elithambile

Sebenzisa iteyiphu yokukala ukuze ulinganise ubude bepayipi elinciphile futhi umake indawo yokusika ngomaka.Sicela uqinisekise ukuthi ubude buhambisana nalokho okusohlwini lwezinto ezibonakalayo, ngaphandle kwalokho, ipayipi elithambile kanye nesistimu yokuhlanganisa ngeke ilingane, futhi isakhiwo sizozinza.

Ngesikhathi esifanayo, sicela usebenzise ifayela ukuze ususe ama-burrs akhiqizwa ekusikeni kwepayipi, ngoba ama-burrs angase aklwebhe abantu futhi enze kube nzima ukufaka ikhava ephezulu.

2.2 Ukufakwa kwesakhiwo sohlaka lwamapayipi anomzimba

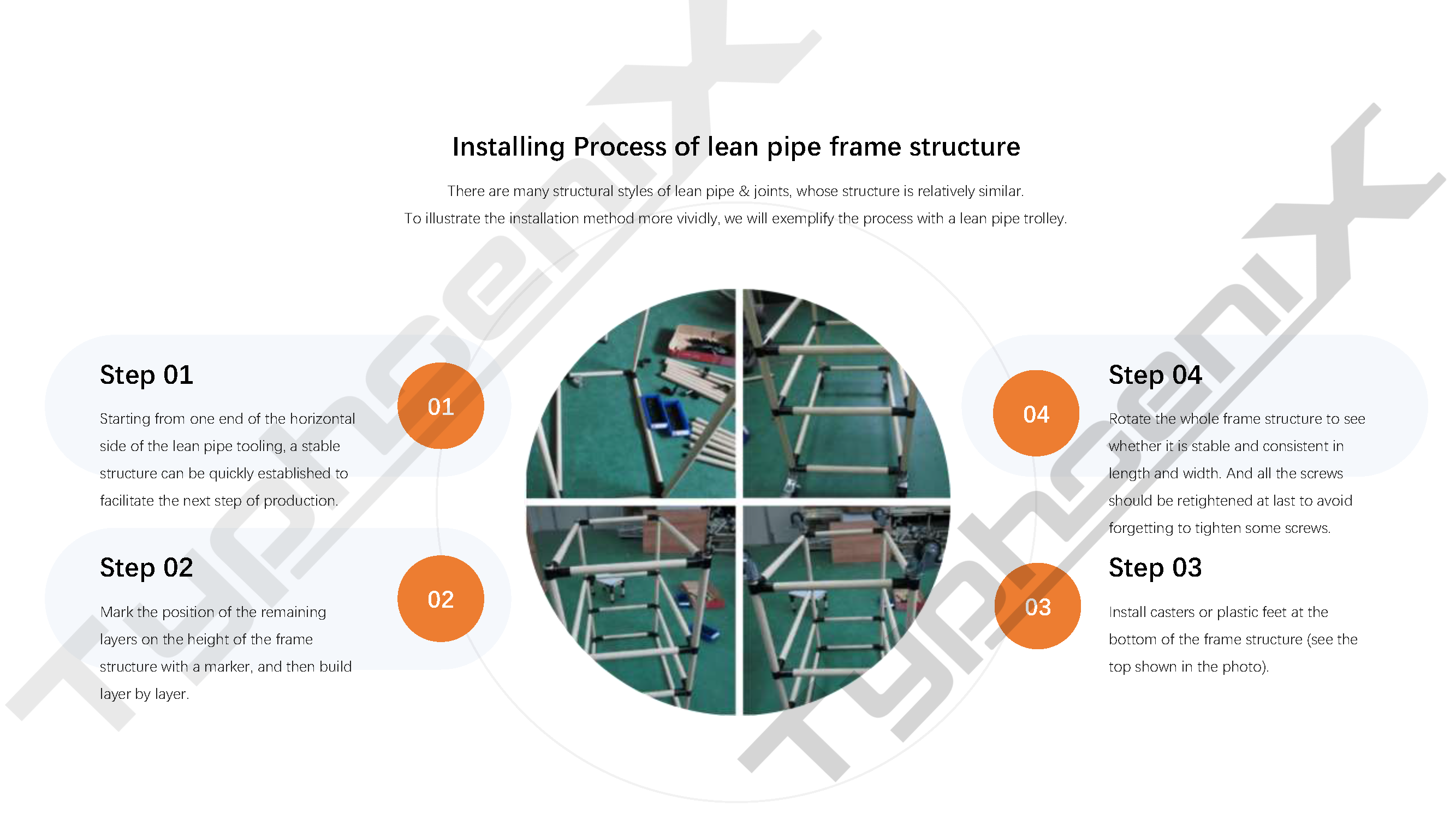

Kunezitayela eziningi zesakhiwo zamapayipi namajoyinti athambile, ukwakheka kwawo kuyafana.Ukukhombisa indlela yokufaka ngokucace kakhudlwana, sizoba isibonelo senqubo ngetroli yepayipi elinciphile.

① Kusukela ekugcineni kohlangothi oluvundlile lwethuluzi lepayipi elithambile, isakhiwo esizinzile singasungulwa ngokushesha ukuze kube lula isinyathelo esilandelayo sokukhiqiza.

Qaphela:Ipayipi elithambile elisetshenziswe esitezi sokuqala kufanele lihambisane nobude, ububanzi nokuphakama, ngaphandle kwalokho Lizofakwa ngendlela engavamile.

②Maka indawo yezendlalelo ezisele ekuphakameni kwesakhiwo sohlaka ngomaka, bese wakha isendlalelo ngokwesendlalelo.Wonke amalunga ensimbi namapayipi anciphile kufanele afakwe endaweni yawo ngokuvumelana nezidingo zokuklama ukuze kuqinisekiswe ukuthi isikulufu sokuhlanganisa sensimbi ngasinye siyaqiniswa endaweni.Akuvunyelwe ukushaya amapayipi namajoyinti ngesando esiqinile.Uma ufaka ikholomu, qiniseka ukuthi i-perpendicular phansi, ukugwema umonakalo odalwe amandla angalingani kulo lonke uhlaka.

③ Faka ama-casters noma izinyawo zepulasitiki phansi kwesakhiwo sohlaka (bona phezulu okuboniswe esithombeni).

Qaphela:Naka ukuqinisa izikulufu kuma-casters.Ngokuqiniswa kancane kancane kwezikulufu, indandatho yenjoloba kuma-casters izokhula kancane kancane, futhi ekugcineni, izoba nemikhono eqinile epayipini elithambile.Uma izikulufi zingaqiniswa, itroli yepayipi elithambile izowa lapho iphusha, okuholela ekulimaleni kwempahla noma izingxenye.

④Zungezisa lonke uhlaka lohlaka ukuze ubone ukuthi luzinzile futhi luyahambisana yini ngobude nobubanzi.Futhi zonke izikulufu kufanele ziqiniswe kabusha ekugcineni ukugwema ukukhohlwa ukuqinisa ezinye izikulufu.

⑤ Engeza ipuleti nezinye izinto kuhlaka ukuze uhlangabezane nezidingo zangempela zomsebenzisi.

3. Ukuhlanza

Hlanza indawo yokusebenza ukuze wenze omunye umsebenzi ube lula.Imikhuba emihle yokusebenza iyisiqinisekiso sokusebenza kahle okuphezulu.Kumelwe sihlakulele imikhuba emihle emsebenzini wethu wansuku zonke.I-6S ibaluleke kakhulu kukho kokubili ukuphathwa kwendawo kanye nomsebenzi wansuku zonke.

Abasebenzi abakhiqiza amapayipi amancane kanye nezinhlelo zokuhlanganisa ngokuvamile badinga abantu abangu-2-3, futhi asikho isidingo esiqinile kumakhono abasebenzi.Kodwa-ke, amapayipi amancane namasistimu ahlangene asebenza kakhulu futhi njengengqalasizinda yokukhiqiza nokusebenza kwenkampani, kufanele athathwe ngokungathi sína.

Ngesikhathi esifanayo, ipayipi elithambile kanye nezinhlelo ezihlangene ngokuvamile zikhulu futhi zihlukahlukene ngendlela, futhi amakhono amaningi ohlelweni lokufaka awakwazi ukuchazwa ngamagama anemininingwane.Lesi sihloko sinikeza kuphela isingeniso esifushane, esingabonisi ngokugcwele amakhono kanye nengqikithi yokukhiqiza ipayipi elithambile kanye nezinhlelo ezihlangene.Ngesikhathi esifanayo, nakanjani kuzoba namaphutha athile ohlelweni lokuhlela.Uma uthola izinkinga ezithile noma uneminye imibono noma iziphakamiso, sicela usithinte.