☞ Advantage

1. Security

The steel pipe ensures the weighing capacity, the plastic surface is smooth to reduce the parts’ surface damage and injury to workers in the workplace.

2. Standardization

Comply with the requirements of ISO9000 and QS9000. The standard diameter and length and the standard matching accessories make them strong versatility.

3. Simplicity

In addition to the description of the load, the lean pipe and joint system products don’t need to consider too much accurate data and structural rules. The production line workers can design and manufacture them by themselves according to their own station conditions. Only one M6 hexagonal wrench is needed to complete the installation process.

4. Flexibility

It can be designed, assembled and adjusted according to its own special needs without being limited by the shape of the parts, the space of the the workstation and the size of the site.

5. Scalability

Flexible, easy to transform, and can expand the structure and function as needed at any time.

6. Reuse

The lean pipe and joint system products are standardized and reusable. When the life cycle of a product or a process ends, the structure of lean pipes and joints can be changed and the original parts can be reassembled to other facilities to meet the new requirements, so save production costs and support environmental protection.

7. Improve production efficiency and improve staff quality

The lean pipe and joint system can trigger the innovation awareness of the employees. The continuous improvement of products and processes can improve production efficiency and improve the quality of employees, to better realize lean production management.

☞ How to Make Lean Pipe and Joints System?

1. Preparation:

1.1 Select appropriate structure and style

Due to different functions, there are several differences in the structure and style of the same lean pipe system applications. How to choose the most appropriate structure and style has a great relationship with the function realization. If you don't know how to select the models, please contact us.

1.2 Confirm Drawing and Scheme

The drawing can predict the possible problems in the production process and correct them in time, to prevent rework in the production process and waste of time and materials. When there are several schemes, preliminary conceptual design can be carried out for each scheme and corresponding drawings can be drawn as far as possible. Calculate the required materials, analyze the production difficulty, and discuss with the department colleagues on the comprehensive production difficulty and cost to determine the plan.

1.3 Create the Material Demand List

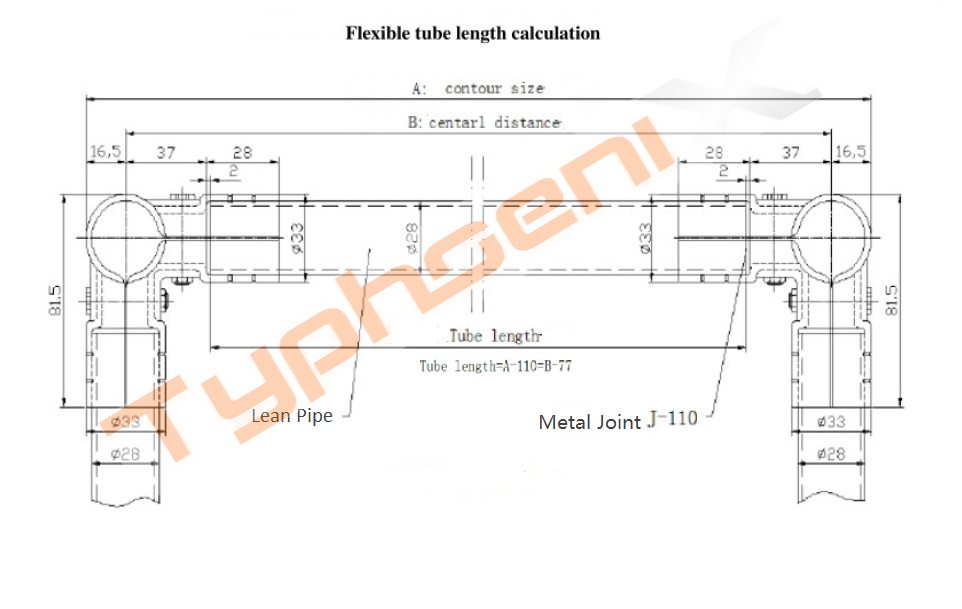

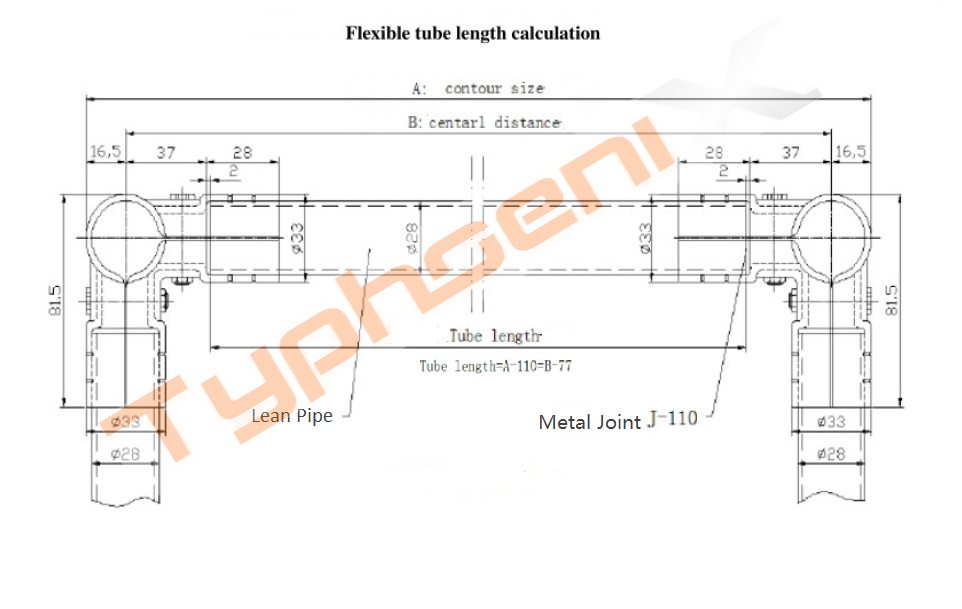

| Metal joints and other accessories can be purchased according to the type and quantity of drawings, while the standard length of the lean pipe is 4 meters, it needs to be cut before use.To maximize the use of lean pipe to avoid waste, a lean pipe list needs to be made and cut it accordingly.The figure below shows the calculation diagram of lean pipe length. The cutting length of lean pipe in each part can be calculated by reference and added to the material demand list. |

|

1.4 Prepare tools

Tools required for manufacturing lean pipe and joint systems include:

• Cutting machine: used to cut lean pipes. If you do not want to equip a cutting machine, we can provide lean pipe cutting service, to provide the corresponding length and quantity of lean pipe according to your requirements.

• Allen wrench: used to connect lean pipe and metal joints

• Tape measure: measure the length of the lean pipe

• Marker: marking

• Curve saw and electric hand drill: used for cutting and drilling the worktable panel (if required)

1.5 Prepare materials

Prepare all the materials listed in 1.3 the Material Demand List, and then start to manufacture.

2. Manufacturing

2.1 Lean pipe Cutting

Use a tape measure to measure the length of the lean pipe and mark the cutting position with a marker. Please ensure that the length is consistent with that on the material list, otherwise, the lean pipe and joints system will be uneven, and the structure will be unstable.

At the same time, please use a file to remove the burrs generated at the cut of the pipe, because the burrs may scratch people and make it difficult to insert the top cover.

2.2 Installing of lean pipe frame structure

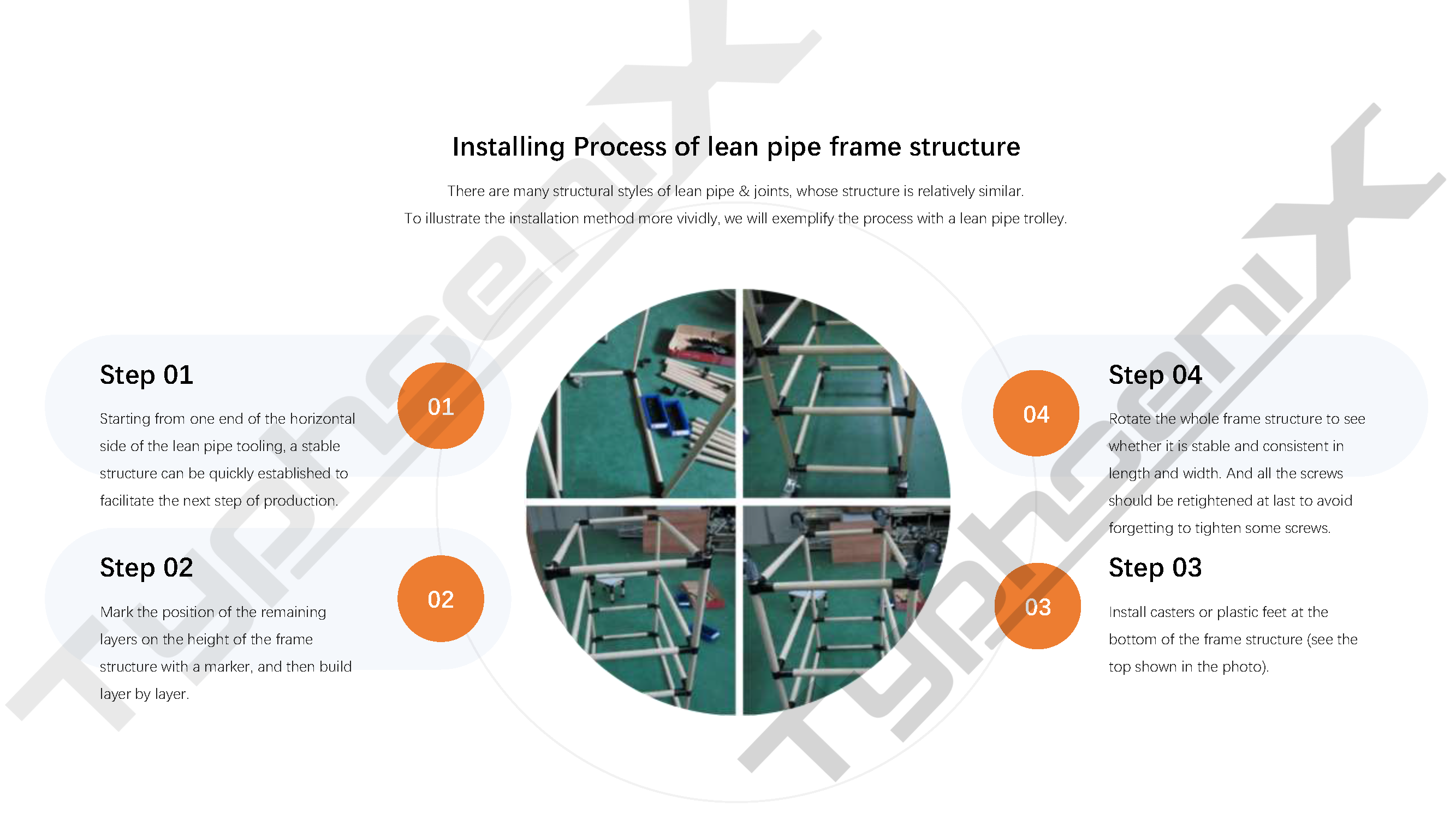

There are many structural styles of lean pipe & joints, whose structure is relatively similar. To illustrate the installation method more vividly, we will exemplify the process with a lean pipe trolley.

① Starting from one end of the horizontal side of the lean pipe tooling, a stable structure can be quickly established to facilitate the next step of production.

Note: The lean pipe used on the first floor must be consistent in length, width and height, otherwise It will be installed in an irregular shape.

② Mark the position of the remaining layers on the height of the frame structure with a marker, and then build layer by layer. All metal joints and lean pipes shall be installed in place according to the design requirements to ensure that each metal joint fixing screw is tightened in place. It is not allowed to hit the pipes and the joints with a hard hammer. When installing the column, ensure that it is perpendicular to the ground, to avoid damage caused by uneven force on the whole frame.

③ Install casters or plastic feet at the bottom of the frame structure (see the top shown in the photo).

Note: Pay attention to tightening the screws in the casters. With the gradual tightening of the screws, the rubber ring in the casters will gradually expand, and finally, it will be tightly sleeved in the lean tube. If the screws are not tightened, the lean pipe trolley will topple in pushing, resulting in the falling damage of goods or parts.

④ Rotate the whole frame structure to see whether it is stable and consistent in length and width. And all the screws should be retightened at last to avoid forgetting to tighten some screws.

⑤ Add plate and other materials to the frame to meet the actual user needs.

3. Cleaning

Clean the workplace to facilitate other work. Good work habits are the guarantee of high work efficiency. We must develop good habits in our daily work. 6S is particularly important in both on-site management and daily work.

The production staff of lean pipe and joints systems generally needs 2-3 people, and there is no strict requirement on the skills of the staff. However, lean pipe and joint systems are highly practical and as the infrastructure of the company's production and operation, they should be taken seriously.

At the same time, lean pipe and joint systems are generally large and varied in form, and many skills in the installation process cannot be described in detailed words. This article only gives a brief introduction, which does not fully reflect the skills and essence of lean pipe and joint systems production. At the same time, there will inevitably be some mistakes in the editing process. If you find some problems or have any comments or suggestions, please contact us.