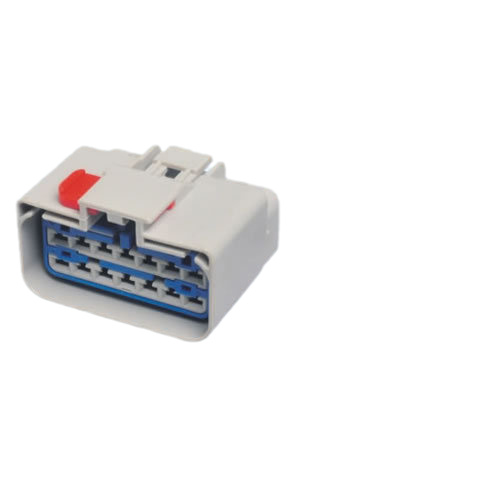

DJ7101-2.8-11 2.8mm Male 10 pin connector with sealed

Specification

| Parts No. | DJ7101-2.8-11 | |

| Reference No. | DJ7101-2.8-11/ 54201017 | |

| Series | 110 (2.80mm) | |

| Number of Positions | 10 | |

| Color | Grey | |

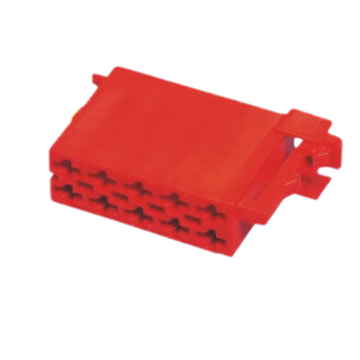

| COMPATIBLE PARTS | Mating Parts | DJ7101-2.8-21 |

| Terminal | DJ615-2.8 | |

| Wire Seal | ||

This Connector are made by PA66 with Grey Color and it is a sealed connector housing. Sealed Connector housing are only required by waterproof wire harness.

Are all wiring harnesses waterproof?

Waterproof is not a universal standard for all automotive harnesses. However, the wiring harness is the nervous system of the vehicle's electrical appliances and plays a vital role in the realization of the vehicle's electrical functions. The power safety of the whole vehicle has always been the most concerned issue of various automobile manufacturers. The working environment of each area may have an impact on the wiring harness. So Waterproofness is a content that cannot be ignored in the design of the wiring harness.

Which wiring harnesses need to be waterproofed?

According to the distribution of dry and wet areas of the vehicle, we divide the vehicle wiring harness into the following parts:

✔ Front Cabin Wiring Harness

✔ Engine Wiring Harness

✔ Instrument Wiring Harness

✔ Interior Wiring Harness

✔ Roof Wiring Harness

✔ Four-Door Wiring Harness

✔ Rear Door Wiring Harness

The front cabin wiring harness, Engine wiring harness and four-door wiring harness are in the wet area. This part of the harness needs to be treated with waterproof protection. And the parts connected to the interior should be sealed with Grommets. The rest of the wiring harness is in the dry area, and the connectors do not need to be waterproof. However, to prevent water from entering the driving cabin when connecting to the outside, waterproofing treatment should be done accordingly.

How to waterproof a wiring harness?

Use waterproof connector including waterproof connector housings, sealed Terminals, Wire seal and Seal plug.

Areas requiring waterproof design must choose waterproof connectors including housings and terminals. At the same time. select appropriate connectors and matching correct waterproof wire seals and sealing plugs according to the waterproof level of each area.

Our waterproof connector products have passed the waterproof test, the following is the waterproof performance test equipment we use:

☞ Use Heat-shrinking tubes

For wiring harnesses in wet areas, the snap-in points between the wires must be protected with heat shrink tubing. We provide different types of Heat shrinking tubes for your choice.

☞ Use Rubber Grommets

Rubber Grommets are commonly used in four-door wire harness and Rear-Door wire harness to for waterproof and sealing protection. You can refer to our Grommets series.

☞ Use Cable Tie

When the wiring harness is fixed on the body sheet metal directly connected to the outside, it is preferable not to make holes on the body, but try to use body studs and cable ties for fixing. If you do have other restrictions, use a waterproof cable tie to secure it.

The waterproof design of the automotive wiring harness is a necessary part of the wiring harness design. Once the waterproof design fails, it is easy to cause various electrical systems to work abnormally, which will not only affect the comfort of the vehicle, but even cause great safety risks. The quality of our waterproof connectors is guaranteed, welcome to inquire!