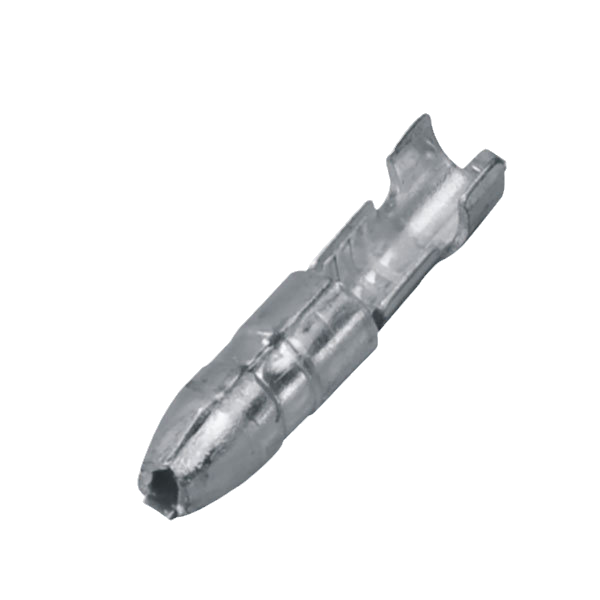

DJ211-4A Copper Tin Plating Shur Plug automotive electrical Terminal

| Parts No. | Reference No. | wire size |

| DJ211-4A | DJ211-4A | 0.85-1.25 |

We also supply the same series of Terminals suitable for different sizes:

| Parts No. | Reference No. | wire size |

| DJ211-4B | DJ211-4B | 1.5-2.5 |

| DJ211-4C | DJ211-4C |

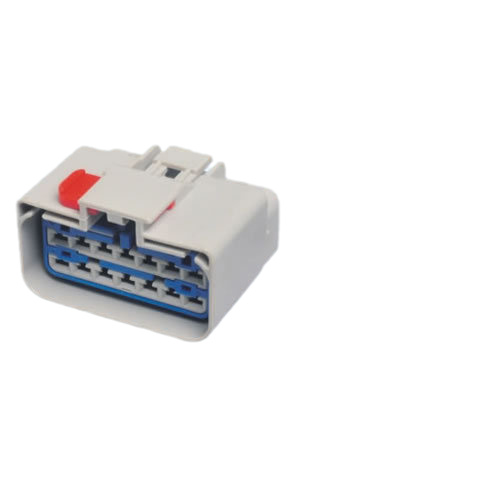

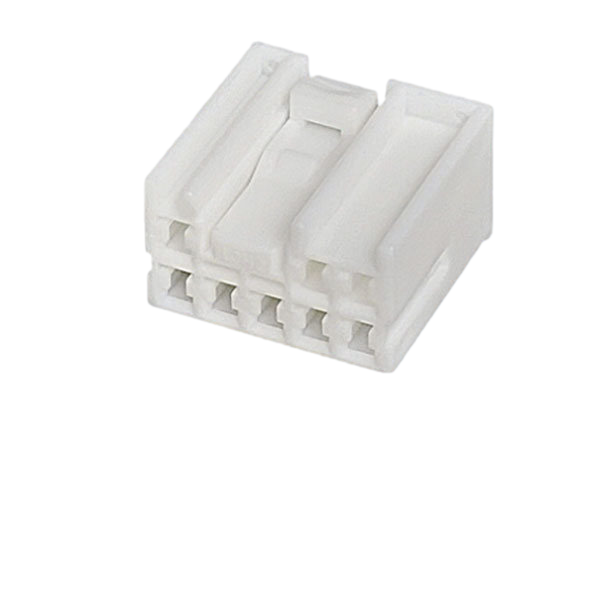

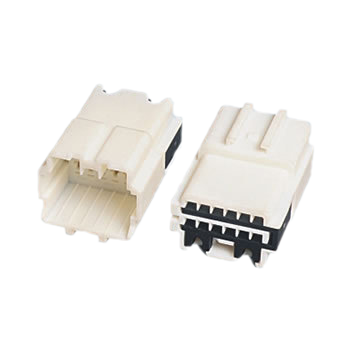

It is used on two types of rubber connectors:

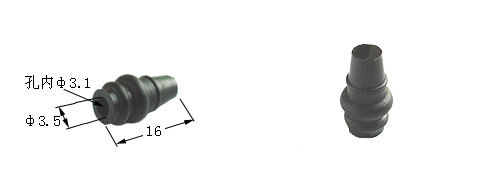

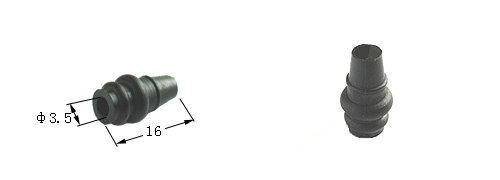

1st one: DJ3011A-4-11/95

2nd one: DJ3011A-4-11/90 (small hole: 3.1 and big hole 3.5)

You can see there are four different Surface Treatments: Bara Copper / Pickling / Tin Plating / Nickel Plating.

Typhoenix shall explain more about their difference.

What is electroplating

Terminal electroplating is an electrochemical process and a redox process, which refers to the process in which simple metal ions or complex ions are discharged on the metal surface by electrochemical methods and reduced to metal atoms attached to the electrode surface, thereby obtaining another metal layer. Electrolysis is a process in which a metal film is attached to the surface of a metal or other material.

why electroplating

The material of the crimping terminal is mostly brass or phosphor bronze. The terminal without any other treatment is called bare copper, also called raw material. The surface shows the true color of the raw material, and some of them have been cleaned by ultrasonic surface. But a metal often cannot meet all the automotive connectors' mechanical properties, electrical properties, and cost requirements. Plated terminals enhance these properties, Specifically, by below points:

☞ Corrosion resistance

The terminal pin is usually corroded in the use environment, such as oxidation, vulcanization, etc. Terminal plating isolates the pin from the environment and prevents corrosion.

☞ Better electrical performance

The conductivity of raw materials such as iron and phosphor bronze is usually below 20%, which cannot meet the requirements for low-impedance connectors. Therefore, high-conductivity metals such as gold are used on the surface to reduce their impedance.

☞ Durability

Plating can protect the terminal base material from wear and corrosion, and establish and maintain the contact interface between the terminals, especially the film control. So that the terminal can maintain its original performance during long-term use.

☞ Nice appearance

The terminal has a glossier and brighter appearance than the material after plating

Coating material

Sn (Tin)

Tin is the most widely used coating material.

✔ Advantages

● Low cost

● Excellent electrical conductivity and solderability

● The tinned layer is soft and has good ductility (toughness) and corrosion resistance, which is conducive to a good fit between the plug and the socket

● The tin coating is bright silvery white for a better appearance

● Safe, non-toxic, and heavy metal free

✘ Disadvantages

● The tin layer is soft and easily damaged

● Lower corrosion resistance

Nickel

✔ Advantages

● Anti-oxidation, and excellent corrosion resistance, nickel has strong passivation ability, can quickly form a very thin passivation film on the surface, and can resist the corrosion of atmosphere, alkali and some acids.

● The electroplated nickel layer has high hardness and high chemical stability in the air, which can improve the wear resistance of automotive electric terminals.

● The crystals are extremely fine, with excellent polishing performance, and can maintain their luster for a long time in the atmosphere.

● Reduces adverse reactions between host metal and coating metal

● Improve adhesion and solderability

Nickel can not only be used as a coating material but also widely used as the underlying material under the precious metal coating. The nickel-plated layer acts as a barrier layer between the copper layer and the gold layer, preventing the mutual penetration of gold and copper, blocking the substrate and the pores, thereby reducing the potential for pinhole corrosion; and providing a hard support layer beneath the precious metal plating, thereby increasing plating life and mechanical strength.The thicker the nickel base layer is, the lower the wear is. However, considering the cost and the roughness of the control surface, the thickness of 50-100u is generally selected.

Gold

✔ Advantages

● The most ideal electroplating material

● Excellent corrosion resistance in any environment

● Excellent solderability

● Good ductility, easy to polish, high-temperature resistance, good resistance to discoloration

● Low contact resistance, good electrical conductivity

● Has certain wear resistance, also ensures the integrity of the signal

✘ Disadvantages

● Soft, must be reinforced with cobalt and nickel

● High cost

Silver

✔ Advantages

● Excellent material for coating the surface of high current terminals, because it will not melt under high current

● Has a strong reflective ability and good thermal conductivity, electrical conductivity and welding performance

● Has strong chemical stability to organic acids and alkalis

✘ Disadvantages

● The cost is quite expensive, but cheaper than gold plating

● Easy to rust in the air with sulfur and chlorine

● Harder than tin, and its resistance coefficient is slightly higher than or equivalent to tin. Potential electron migration may lead to potential risks of connectors.

Electroplating process

Electroplating is an electrochemical process that includes the following three steps: pre-treatment, electroplating, and post-treatment.

① Pre-treatment

The pre-plating treatment of automotive connector terminals is one of the important factors in determining the quality of electroplating. 80% of electroplating failures are caused by insufficient surface treatment.

Pretreatment consists of several processing steps: cleaning, deburring, and activation.

Activation: Parts need to be dipped in acid to remove oxide film and gently scrape the surface for better-plated metal adhesion.

② Electroplating

During electroplating, the plated metal or other insoluble material is used as the anode, the workpiece to be plated is used as the cathode, and the cations of the plated metal are reduced on the surface of the workpiece to be plated to form a plated layer. This enhances the electric terminal's corrosion resistance, increases hardness, prevents abrasion, and improves electrical conductivity, smoothness, heat resistance and surface aesthetics.

③ Post-treatment

Post-treatment includes rinsing, cleaning, sealing, neutralizing, and drying after plating. 100% of the coating chemistry must be removed from the coated part.

Typhoenix provides automotive crimping terminals with different surface treatment plating for your choice, if you have special requirements, please let us know in advance.