PTG series wire harness wrapping PVC tubing cable sleeve

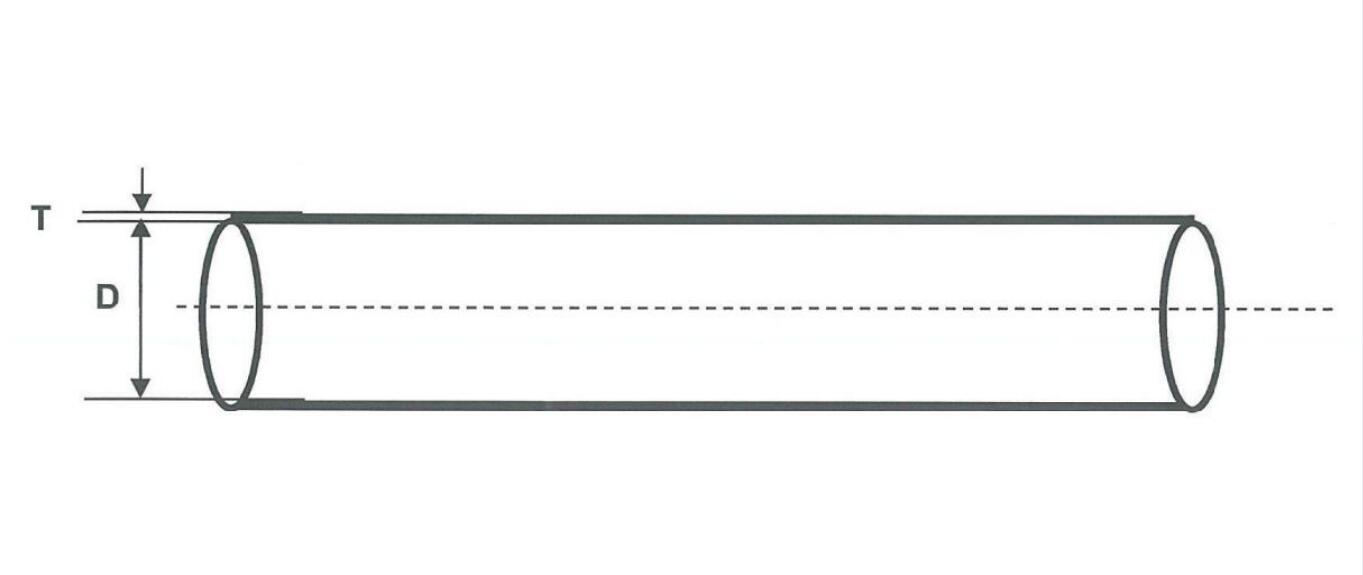

| Parts No. | Reference No. | Inner Diameter D (mm) | Standard thickness dimensions T (mm) |

| PTG-3 | PTG-3 | 3.0±0.5 | 0.40-2.00 |

| PTG-4 | PTG-4 | 4.0±0.5 | 0.40-2.00 |

| PTG-5 | PTG-5 | 5.0±0.5 | 0.40-2.00 |

| PTG-6 | PTG-6 | 6.0±0.5 | 0.40-2.00 |

| PTG-7 | PTG-7 | 7.0±0.5 | 0.40-2.00 |

| PTG-8 | PTG-8 | 8.0±0.5 | 0.40-2.00 |

| PTG-10 | PTG-10 | 10.0±0.5 | 0.40-2.00 |

| PTG-14 | PTG-14 | 14.0±0.8 | 0.40-2.00 |

| … |

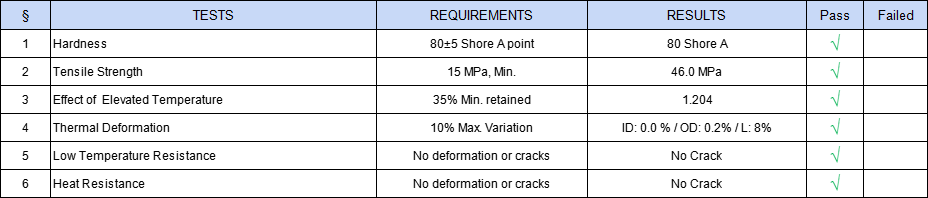

The temperature resistance test

According to different temperature resistance grades, our PVC tubing are divided into two types:

Grade A(105℃):

Identification of the Request: FORD ES-2U5A-1A263-AA

● Long term aging (3000h): 100°C

● Short term aging (240h): 125°C

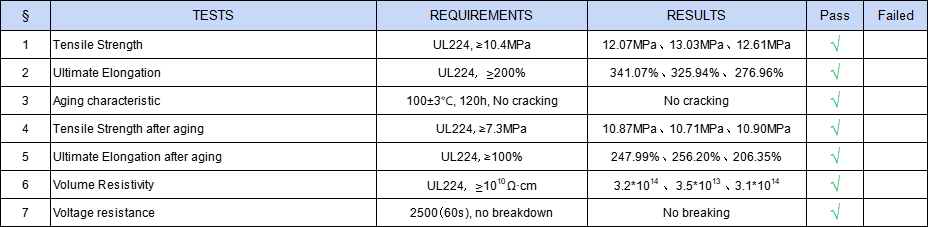

Grade B(70℃):

Identification of the Request: UL224

● Aging characteristic (120h): 100±3°C

Cross-Reference Table

|

Product |

EF NO. |

Raychem |

Sumitomo |

DSG-Canusa |

Alpha |

3M |

LG |

Temperature resistance |

Shrinkage |

|

|

Heat Shrink Tubing

|

Halogen-free Environmental Protection Tubing |

EFG-HFT(300) |

ZH4 |

SUMITUBE-NHR4 |

125°C |

2:1 |

||||

|

EFG-HFT(600) |

ZH2 |

SUMITUBE-NHR2 |

125°C |

2:1 |

||||||

|

EFG-HFT(3X) |

125°C |

3:1 |

||||||||

|

EFG-HFT(4X) |

125°C |

4:1 |

||||||||

|

EFG-HFT(LS) |

DERAY LSB |

125°C |

2:1 |

|||||||

|

EFG-HFT(YG) |

DCPT |

CPX201 |

125°C |

2:1 |

||||||

|

EFG-PET |

125°C |

2:1 |

||||||||

|

Conventional Sleeving |

EFG-101 |

CGPE-105 |

C |

DERAY-HB |

GSHS-1625 |

105°C |

2:1 |

|||

|

EFG-301 |

105°C |

2:1 |

||||||||

|

EFG-135F |

RNF-100 |

135°C |

2:1/3:1 |

|||||||

|

Marker Sleeving |

EFG-MT |

125°C |

2:1/3:1 |

|||||||

|

EFG-MT(HX) |

135°C |

2:1/3:1 |

||||||||

|

EFG-MT(RO) |

D-SCE |

135°C |

2:1/3:1 |

|||||||

|

EFG-MT(TAG) |

HLX |

125°C |

— |

|||||||

|

Medium Wall and Heavy Wall Sleeving |

EFG-MWT |

135°C |

3.5:1/4:1 |

|||||||

|

EFG-MWTA |

MWTM |

CFM |

IMCSN |

LG-PMWT |

135°C |

3.5:1/4:1 |

||||

|

EFG-HWT |

135°C |

3.5:1/4:1 |

||||||||

|

EFG-HWTA |

WCSM/ |

CFW |

FIT700 |

ITCSN |

LG-PHWT |

135°C |

3.5:1/4:1 |

|||

|

EFG-HWT(6X) |

135°C |

6:1 |

||||||||

|

EFG-HWTA(6X) |

HRSR/ |

CFHR |

FIT621 |

135°C |

6:1 |

|||||

|

EFG-MWT(FR) |

135°C |

3.5:1/4:1 |

||||||||

|

EFG-MWTA(FR) |

135°C |

3.5:1/4:1 |

||||||||

|

EFG-HWT(FR) |

135°C |

3.5:1/4:1 |

||||||||

|

EFG-HWTA(FR) |

BSTSFR/ |

FCFW |

HDT |

135°C |

3.5:1/4:1 |

|||||

|

EFG-MWTM |

PLA |

135°C |

3.5:1/4:1 |

|||||||

|

Special Design Heat Shrink Tubing |

EFG-KYNAR(150) |

RT-375/ |

K2/K3 |

GSHS |

150°C |

2:1 |

||||

|

EFG-KYNAR(175) |

RW-175/ |

K |

CKN-175/ |

FIT350 |

GSHS-1675 |

175°C |

2:1 |

|||

|

EFG-KT |

RT-375/ |

K2/K3 |

GSHS |

150°C |

2:1 |

|||||

|

EFG-1000 |

RNF-100 |

CPX 100 |

135°C |

2:1 |

||||||

|

EFG-PTFE |

TFE |

CTFE 250 |

200°C |

2:1 |

||||||

|

EFG-FKM |

VITON |

FE3 |

DERAY VT220 |

FIT650 |

200°C |

2:1 |

||||

|

EFG-DR |

DR-25 |

DERAY V25 |

200°C |

2:1 |

||||||

|

EFG-RSF |

HFT 5000 |

125°C |

2:1 |

|||||||

|

Dual Wall Sleeving |

EFG-DWT |

TAT-125/ |

SCN2/W3B2 |

125°C |

2:1/3:1/4:1 |

|||||

|

EFG-DWT(1000) |

ATUM |

B2 |

CPA100 |

FIT221 |

GSHS |

135°C |

2:1 |

|||

|

EFG-DWT(2000) |

AP-2000 |

O |

GSHS-2690NW |

125°C |

1.5:1 |

|||||

|

EFG-DWT(3000) |

ES-2000 |

SA2 |

CBK |

FIT421 |

GSHS-4635WS |

125°C |

4:1 |

|||

|

EFG-DWT(4000) |

ES-1000 |

125°C |

4:1 |

|||||||

|

EFG-DWT(135F) |

ATUM |

135°C |

2:1/3:1/4:1 |

|||||||

|

EFG-DWT(RO) |

RBK-ILS |

125°C |

4:1 |

|||||||

|

EFG-DWT(RX) |

RBK-VWS |

125°C |

4:1 |

|||||||

|

EFG-DWT(FR) |

FL-2500 |

125°C |

4:1 |

|||||||

|

EFG-DS 406 |

D-406 |

W7N |

125°C |

4:1 |

||||||

|

EFG-OFS |

105°C |

— |

||||||||

|

Nonshrink tubing

|

Polytetrafluoroethylene Sleeving |

EFG-TT(L) |

200°C |

— |

||||||

|

EFG-TT(T) |

200°C |

— |

||||||||

|

EFG-TT(S) |

200°C |

— |

||||||||

|

PVC Tubing |

EFG-300(PVC) |

105°C |

— |

|||||||

|

EFG-600(PVC) |

105°C |

— |

||||||||

|

PE Tubing |

EFG-300(PE) |

125°C |

— |

|||||||

|

EFG-600(PE) |

125°C |

— |

||||||||

|

Glass FiberTubing, Silicone Tubing, PET Braided Sleeving |

EFG-SGS |

200°C |

— |

|||||||

|

EFG-SRS1 |

200°C |

— |

||||||||

|

EFG-SRS2 |

200°C |

— |

||||||||

|

EFG-SRT |

200°C |

— |

||||||||

|

EFG-PETN |

150°C |

— |

||||||||

Our laboratory

What is PVC?

The PVC is a very common material in the market at present. The main component is Polyvinyl chloride. It is a polymer polymerized by vinyl chloride monomer (VCM) with peroxide, azo compound and other initiators or by free radical polymerization mechanism under the action of light and heat.

Why do we use PVC tubing to protect the wire harness?

The wire harness is fixed on the whole vehicle body, and the damage of the harness directly affects the performance of the automobile circuit. Therefore, the external protection of the harness plays a vital role. Reasonable external protection materials and binding methods can not only ensure the quality of the harness, but also reduce the cost and improve the economic benefit.

We use PVC tubing to protect the wire harness because it has excellent performance:

✔ PVC Tubing has a relatively low price.

✔ PVC Tubing has a good appearance. The inner and outer walls of the tube are smooth, and the color is uniform.

✔ PVC Tubing is soft and elastic, so it is mainly used at the branch of harness bend elbow to make the conductor transition smoothly.

✔ PVC Tubing has good physical properties: certain heat resistance, ductility, and toughness.

✔ PVC Tubing has excellent electrical properties, acid, and corrosion resistance.

✔ PVC Tubing has high flame retardant performance, our PVC tubing meeting the flame retardant grade certified by UL 224, VW-1 and JQA F-mark.

✔ PVC Tubing has different temperature resistance grades,We can provide grades A and B,The heat-resistant temperature of B is 70 ℃, and A is 125 ℃.

✔ PVC Tubing has wide range of applications: in addition to automobiles, it can also be used in electronic components, household appliances, machinery, toys, and sporting goods.